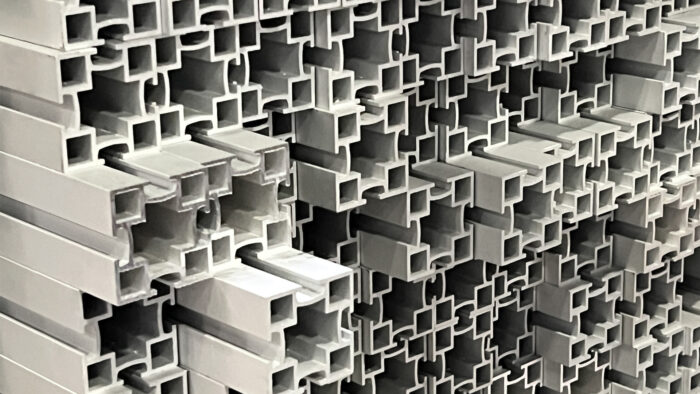

Agam has over 130 proprietary extrusions and over 500 parts and accessories all engineered to give you endless design options. Agam’s components easily interlock to create dynamic and functional structures for a variety of applications.

System Extrusions

From large to small, round to square, soft or hard panel applications, Agam has an extensive library of extrusions to meet every need.

Accessories

With over 500 parts and accessories, we can enhance the utility and aesthetic of your design. Custom parts are also available.

Check out our Instagram @agamgroup for weekly inspiration