Specialized Fabrication Services

With a skilled and tenured production staff, highly specialized equipment, 115,000 square feet of manufacturing space, and forty years of experience, Agam offers unparalleled manufacturing capability with a broad range of operations to create custom solutions fast.

Precision Custom Cutting

Whether it be simple cuts or complex shapes, Agam has state-of-the-art cutting equipment for every type of job. Our digital and CNC equipment assures quality and consistency.

-

Laser Cutter

-

Water Jet

-

CNC Router Tables

-

Single and Double Headed Miter Saws

Shaping and Forming

Bending, curving, and shaping components is essential for delivering special design elements. Agam’s specialty team has the right equipment to execute with precision.

-

Multiple CNC Roller Benders

-

CNC Press Brake

-

End Milling Machines

Machining

Agam produces the majority of its over 500 parts and accessories in-house. Two machining centers fully automate this process so the parts we need are always on-hand. Volume custom parts can also be made with ease.

-

Two Vertical Machining Centers

Powder Coating

Our in-house powder coating line delivers incredible finishes to beautify our customers’ designs. Choose from 100s of colors and various textures and sheens. This environmentally friendly process doesn’t use harmful solvents.

-

Spray booth and 75 foot curing oven.

Production Facility

Located in the Washington DC -Baltimore corridor, Agam’s production facility is under one roof to ensure efficient throughput and a single point of control. This means quality production delivered fast.

-

115,000 square foot facility

-

250 foot overhead crane

-

Extensive inventory

-

Shipping and receiving services

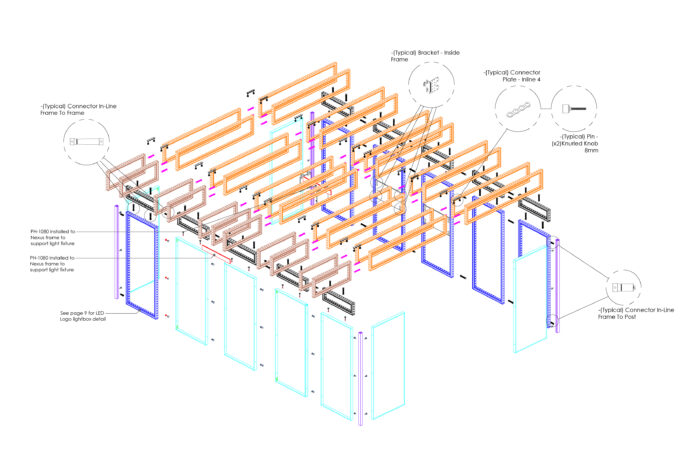

CAD Engineering

Agam’s CAD Engineering department can help you translate your design concept into a production reality. We work to preserve your design integrity while maintaining budget and structural integrity.

-

Drawings for the quote process

-

Production drawings

-

Assembly drawings

Check out our Instagram @agamgroup for weekly inspiration